CASE STUDIES

SEA COLONY BEACH AND TENNIS RESORT, Bethany Beach, DE

LASER LIFT, completed April 2010

Sea Colony Beach & Tennis Resort hired Sport Builders to renovate 14 outdoor Har Tru Tennis courts. An evaluation of the Har Tru courts, concluded they were in need of a laser lift because the Har Tru base had become extremely thin allowing stones from the courts’ base to penetrate the playing surface. The erosion of the court base was also causing slope failure, surface undulations and low spots. There was also a variation of base thickness causing inconsistencies in moisture levels and lack of surface surface compaction. During the warm summer months, the courts were constantly dry because of inconsistency with the irrigation system. The Har Tru base no longer had the ability to retain moisture.

Irrigation is the primary component needed to create ultimate Har Tru playing conditions. The solution to dry courts was to design a new above-ground irrigation system which featured a two watering zones per/court with four high-impact heads per zone. A state of the art controller (Toro - Baseline Controller) was installed that allows operation from a cell phone. The courts were then re-graded to establish a 1” fall every 30’ on single plane. This ensured that the courts had the correct pitch needed for moisture retention and natural water run-off. A new one-inch layer of Har Tru was also installed and laser graded to give the courts the base density they needed.

PROJECT FEATURES:

Irrigation System - A complete new system was installed featuring the Toro Baseline Controller. The entire irrigation system can actually be monitored and controlled from an iPhone or cell phone. Each court has 2 sprinkler zones with 8 heads per/court. This allows for precise control over the amount of water each court receives and courts can be watered independently of the court next to it.

Brick Curbing Reconstruction - A new brick curb was constructed to contain the final Har Tru surface. The brick followed the corrected slope of the new courts and provided an nice clean edge for each court battery.

Grade Correction - The courts had too much pitch which lead to surface erosion and premature drying. Also, after heavy rain storms, Har Tru was constantly being washed off the court. The courts were laser grading to correct the slope by reducing the amount of slope.

Laser Lift - A new 1” layer of Har Tru was installed and laser graded to correct the inconsistency’s found in the court base. The surface was compacted and top dressed for ultimate playing conditions. Sport Builders also installed playing.

PROJECT FEATURES:

Net Posts - Because of the significant elevation change, new net posts were installed. Typically, new net post sleeves are set in a concrete foundation. This allows net posts to slide in and out easily.

Irrigation System - Installation of an above ground irrigation system. We actually cut channels into the original asphalt to protect the PVC pipe during construction. The system was connected to an automatic controller/timer which allows the courts to be watered in the middle of the night.

Brick Curbing - A brick curb was installed around the entire perimeter in a mortar bed which contains all the stone and Har-Tru materials. The brick follows the slope necessary for Har Tru courts and was constructed just inside the fence line which allows re-use of the fence.

Stone Base Constrction - 3/4” Modified stone was installed over the existing asphalt courts. The stone provided the necessary slope change and a solid base for a Har-Tru court. The old asphalt serves as a great foundation for the Har Tru courts and does not create a drainage problem actually improving capillary action, the ability for water or moisture to return to surface from below the court. The stone was laser graded and compacted to ensure the correct slope.

Stone Dust Construction - A 1” layer of stone dust was installed over the modified stone base which provided a platform for Har-Tru and it helped retain moisture under the court surface.

Har-Tru Installation - The final 1” Har-Tru layer was installed. This is the final playing surface and it was prepared for play by laser grading the surface to ensure an even court.

Final Playing Surface - The court was prepared for play by rolling the court, additional top-dressing material was installed followed by the installation of the playing lines.

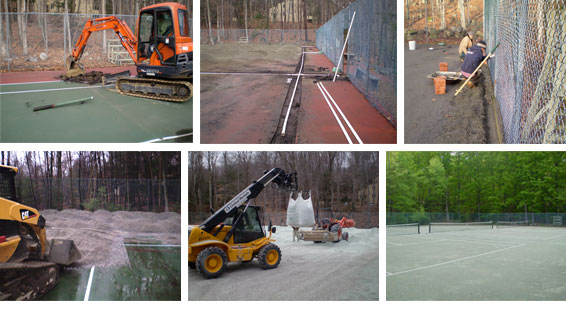

LAKERIDGE, Torrington, CT

HAR-TRU CONVERSION, completed October 2008

Sport Builders converted 5 all-weather hard courts that were significantly cracked into a into Har-Tru courts. When converting hard courts to Har-Tru, the new Har Tru surface is actually constructed right on top of the existing asphalt. The conversion procedure began by installing a 6” layer of modified stone right on top of the existing hard tennis court surface. The stone serves as the new base of the court and it’s used to change the slope of the existing court (Har-Tru courts have less pitch than hard courts). A 1” layer of stone dust was installed which served as an important separation layer before the finished 1” layer of Har-Tru was installed which serves as the final playing surface. During the procedure, a Belgium block perimeter was installed to contain all the aggregate and Har-Tru materials. Irrigation was also installed which maintains the playing surface. The existing fence was used although some minor modifications were required to accomodate the new higher court elevation.

GREENWICH COUNTRY CLUB, Greenwich, CT

HYDROCOURT CONVERSION, completed May 2011

Looking for less maintenance and more consistent playing conditions, Greenwich Country Club decided to convert their existing Har Tru courts into Hydrocourts. Sport Builders constructed six new Hydrocourts right on top of the existing Har Tru courts. HydroCourt is a self-regulating irrigation system that waters the court from underneath the playing surface. Each court was constructed with six, fully-lined, individually-controlled cells and monitored by a water control box allowing adjustment to be fined tuned to player preferences. Increasing the water in the control boxes increases the amount of water the court recieves. Once the appropriate water level is achieved a float valve and an overflow pipe inside the control box keep the water level constant and thus moisture levels on the court. The Hydrocourt advantage includes perfect playing conditions 24/7 because the surface stays uniformly wet, smooth and firm for a consistent bounce and exceptional footing. Hydrocourts also allow more available court time by eliminating the need for mid-day shutdowns to water the courts. Hydrocourts are playable during light rains and immediately playable after hard rain storms. Maintenance is cut in half by eliminating daily rolling and decreasing the amount of court brushing required. Water usage is cut by approximately 40%. With watering from below, some players feel like Hydrocourts are air conditioned; they can be as much as 20 degrees cooler than a standard hard court.

PROJECT FEATURES:

Hydrosystem installation - The sub-surface irrigation system that controls moisture levels in the court was installed on each court.

Preparation - The existing Har Tru court base was regraded to ensure the correct slope. A layer of stone dust was also installed prior to the Hydrosystem installation for additional stability and to improve planarity of the existing surface. A brick curb was also installed around the entire court battery which contained the sub-base and final Hydroblend surface materials.

Hydrosystem Installation - The subsurface irrigation system (hydrosystem) is installed. Necessary plumbing

including the main water line connections were also made to bring water to the court.

Hybrid Sprinkler Head System - A simple sprinkler system was installed to help with spring court preparations.One zone with 4 sprinkler heads for each 2 court battery. In the Northeast, the actual Hydrosystem may not be necessary for a couple of weeks into the season due to cold and damp spring conditions. The sprinkler heads serve as supplemental irrigation until the system is charged keeping the top dressing damp.

Hydro Sand Installation - A special stone dust blend is filled, laser graded and compacted into each hydro cell (6 cells per/court). The stone is approximately 6” thick and it allows water to pass upwards into the playing surface,called capillary action.

Final Playing Surface - The final 1” Hydroblend layer is installed over the stone dust. The Hydroblend is laser graded to ensure the correct pitch and a level court.

Final court preparations - The courts were prepared for play which included the installation of new net posts, on court cabana bench, final surface preparations that include surface compaction, final top-dressing and line installation.